Transmission Control Unit (TCU) Explained

Transmission control unit - what is it?

The transmission control unit (TCU) is an automotive electronic control unit that calculates how and when to change gears in your automatic vehicle, whilst maintaining optimum performance, fuel economy and shift quality. A modern automatic transmission ECU/TCU will use sensors from around the vehicle in conjunction with data provided by the engine control unit. With this information combined into one place, the transmission control unit then calculates what gear should be selected at any given time based on many factors including engine speed, vehicle speed and measured road conditions; it can even adjust its own settings according-to driver habits!

The TCU is an important part of any automatic vehicle and its correct operation is crucial to the vehicles performance and driveability. A transmission that is not operated correctly can cause a number of problems including poor fuel economy, harsh or erratic gear changes and even complete transmission failure. This is why the TCU monitors all incoming data against pre-set tolerances and parameters. If these conditions are not met the transmission ECU will log a fault report and even take action, such as forced limp mode, to prevent further problems.

Traditionally the transmission system was controlled by the driver via a manual gearbox with a pedal that would operate the engagement and disengagement of the clutch and a lever to change gears. However with the growing need to reduce ecological impact and increase driveability, the transmission has become computer/electronically controlled. Adding electronics will inevitably complicate a systems workings but the introduction of transmission control units has brought progressive advantages such as:

- Increased driveability with smoother and quieter gear changes

- Ease of use

- Increased performance and economy

- Reduced emissions

- Increased reliability

- Self-diagnosis

As automobiles become more autonomous it’s important that we understand what each module does in the vehicle. The automatic transmission takes away the need for driver input, reducing driver fatigue, and can often provide a smoother drive experience whilst also aiding in fuel economy and lower emissions.

The transmission's gears shift based on signals generated from the onboard computer that processes data about how far and fast you're going and what gear should be used. The critically important part of this process is the Transmission Control Module/Unit (TCM or TCU), which helps regulate those changes by monitoring inputs like engine speed, vehicle speed and driving conditions imparted by other electronic control modules in the vehicle.

Automatic, fully and semi-auto alike, transmissions have been in use since the late 1980’s shifting from manual hydromechanical control to partial or fully automated systems in a variety of designs. The auto gearbox can be a confusing subject for many people, there are dozens of different types, with brand names that can be difficult to keep up with (or remember), but essentially they all do the same thing: make your car move!

- What does it do?

- Transmission control outputs

- TCU controlled transmission types

- What goes faulty?

- Videos

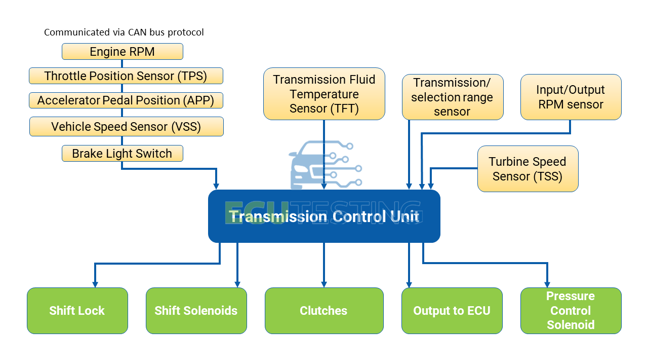

The purpose of the transmission ECU is to control the shift points and shift quality. To do this, it has to know what gear you're in and how fast you're going. The ECU is constantly monitoring this data, changing shift maps according to driving conditions and driver input. The transmission ECU constantly monitors sensors for transmission fluid temperature and pressure as well as engine RPM, throttle pedal position (or how much you're pressing the accelerator), engine coolant temperature, gear lever gear/mode selection, vehicle speed, engine load (from the MAF sensor via the engine ECU) and other signals that let it know what's going on with your vehicle.

Transmission/selection range sensor

Monitors and compares the gearbox speed against the desired gear and the actual gear selection.

Input/Output RPM sensor

Whilst the input sensor delivers the speed of your transmission's input shaft to the TCU, the output RPM sensor monitors the corresponding output shaft. By using these two rpm sensors and the range sensor the transmission ECU can calculate the actual gear ratio and decide how often gears would need to be changed by comparing actual speeds and selections versus desired ones.

Using these inputs , the ECU calculates when and how to shift the automatic transmission. The TCU/TCM monitors its output for malfunctions, keeping your vehicle from accelerating or slowing down more than it should. By using these inputs and machine learning algorithms modern automatic transmissions can also learn your driving style and change its shift mapping to adapt to your needs. This is known as Adaptive Learning and is a continuous process offering better performance, reduces frequency and cost of maintenance and can help the transmission itself, and fluid, last longer.

The transmission ECU usually relies on sensors that are already collecting data for other systems, rather than add further unnecessary sensors and wiring which will overcomplex the system and add weight to the vehicle. For example the wheel speed sensors (WSS) are monitored by the ABS module to determine how fast the vehicle is going, the throttle position sensor (TPS) measures how open the throttle valve is, monitoring the air intake of the engine and requested demand of the driver. All of this information is shared with the transmission control module via CAN (controller area network) communications protocol.

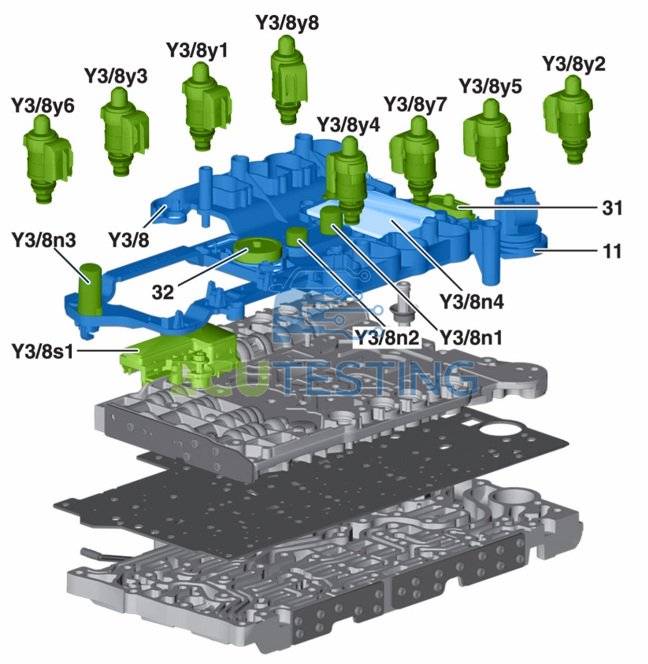

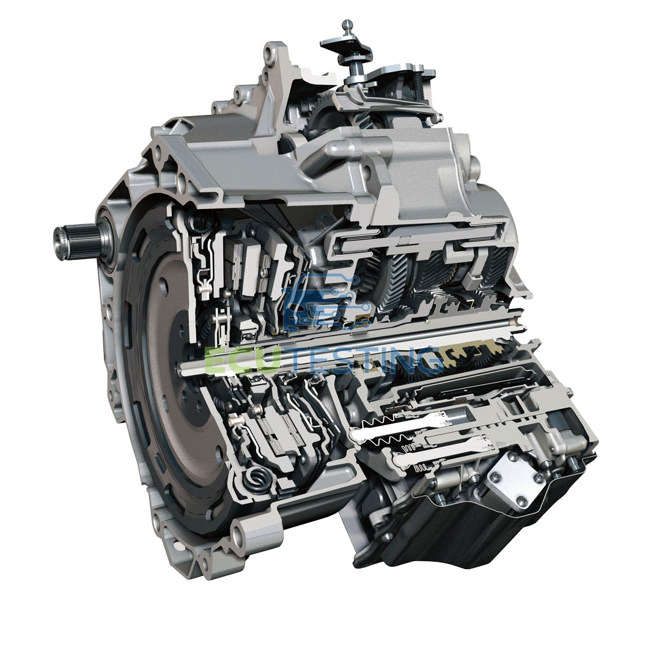

However as technology progresses there are more and more sensors being built directly into the transmission module. A good example of this is the Mercedes 7G-Tronic for the 722.9 gearbox which has the transmission control unit integrated within the transmission itself which allows for a reduction of wiring between the TCU and the valve body; lowering overall weight, electromagnetic interference and increasing efficiency. Speed, temperature, range and pressure sensors are built into the TCU and allow the control module to collect and analyse data about the current state of the transmission and fluid which it then uses to optimise gear changes and monitor for errors. It manages high frequency electro hydraulic solenoids which control hydraulic valves within the valve body letting in transmission fluid under specific pressure. In turn the valve body is responsible for the hydraulic control in the automatic transmission by managing fluid flow to the various sections of the gearbox and the torque converter, via a labyrinth of fluid channels.

11 Plug connection

31 Oil control float 1

32 Oil control float 2

Y3/8 Electric control module/TCU

Y3/8n1 Turbine rpm sensor

Y3/8n2 Internal rpm sensor

Y3/8n3 Output rpm sensor

Y3/8n4 Transmission control module

Y3/8s1 Selection range sensor

Y3/8y1 Working pressure control solenoid valve

Y3/8y2 K1 clutch control solenoid valve

Y3/8y3 K2 clutch control solenoid valve

Y3/8y4 K3 clutch control solenoid valve

Y3/8y5 B1 brake control solenoid valve

Y3/8y6 B2 brake control solenoid valve

Y3/8y7 B3 brake control solenoid valve

Y3/8y8 Torque converter lockup clutch control solenoid valve

Shift lock

If the brake pedal is not depressed, the transmission ECU will lock the selector lever with a shift lock solenoid to prevent a driving range from being chosen.

Shift solenoids

Electronic automatic transmissions use electrical solenoids to shift gears. Simple electronic control systems utilise the solenoids to alter the shift points in an existing valve body, while more complex designs employ them to manipulate clutches indirectly by way of a much simpler valve body.

Pressure control solenoids

Even today's sophisticated automatic transmissions retain their hydraulic roots, which require tight pressure control. Whereas older designs operated via single line pressure control, modern transmissions make use of multiple pressure control solenoids allowing precise pressure control, generating improved shift speed and quality.

Torque converter clutch solenoid (TCC)

A TCC solenoid regulates the torque converter electronically in many electronic automatic transmissions. The torque converter will no longer multiply torque force once fully locked, and instead spins at the same speed as the engine. This increases fuel efficiency considerably.

Clutch control

In order to select optimal gear the transmission ECU will actuate a series of clutches to realign planetary gear sets within the transmission to attain the most efficient driving gear.

Output to ECU

The engine ECU receives constant input from the transmission ECU and because of this can react quickly and accordingly. For example in order for the transmission to maintain smooth and correct shift changes the engine ECU will reduce fuel quantity flow or retard ignition timing. Lowering the amount of fuel supplied to the engine for a brief period will reduce gearbox strain when using heavy throttle. This allows automatic transmissions to shift smoothly even on engines with a lot of torque, which would otherwise result in a harsh shift and even gearbox damage.

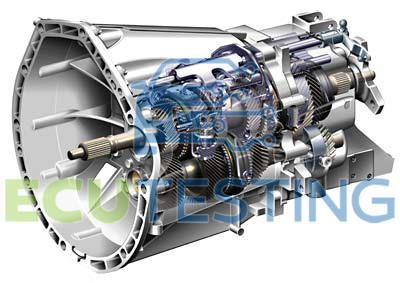

Automatic transmission - This sealed and enclosed design keeps the engine and transmission spinning independently and transfers power from the engine to the gearbox when needed using oil pressure and a series of planetary (epicyclic) gears. The TCU is a sophisticated device that controls many different functions. It controls oil pressure and decides which valves open and close, as well as regulating electronic solenoids which are used for operating multi-plate clutches and will lock up torque converters to reduce slipping. The TCU also offers various driving modes which are fully selectable by the driver.

Automated manual transmission – is mechanically similar to manual transmissions, however there is no clutch pedal. Instead, all of the clutch and gear shift work is operated by actuators, controlled by a transmission ECU (TCU) often built into the clutch actuator. Gearshift patterns are pre-programmed into the transmission control unit which determines the optimum operating sequence for various components, such as clutch and gear actuators which engage when necessary through an automated process once certain input requirements are met.

Continuously variable transmission – Is essentially a single speed electronically controlled unit with infinite gear ratios, basically an endless number of gears with no pause between shifts, this makes it possible to have exactly the right gear for any driving condition. A CVT gearbox simplifies the process of accelerating by using two cone-shaped variable diameter pulleys that are connected via a V shaped drive belt. One pulley is connected to the engine and the other to the wheels. As the engine revs, the associated cone moves according to the amount of power required, this causes the other cone to adjust accordingly, maintaining the same tension, determining how the vehicle accelerates. The result is that the engine's RPMs can be maintained at its most efficient speed also making this system ideal for automobiles where high torque needs are present. Because of this the CVT does not have gears like traditional automatic transmissions, so there is no loss of torque during gear changes, it produces less noise than traditional automatic transmissions do, and requires less maintenance than traditional automatic transmissions.

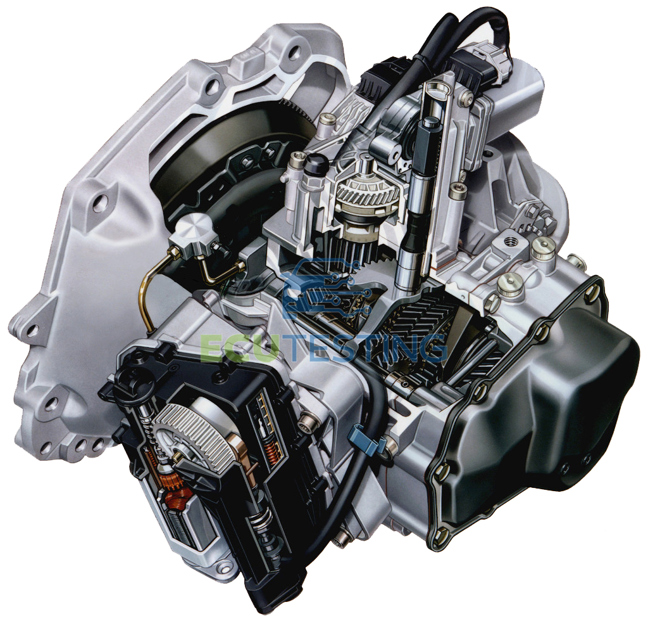

Dual/Twin Clutch transmission - This transmission uses separate clutch packs to drive odd and even gear sets respectively. Akin to two separate transmissions and clutches all in one, which allows gears to be pre-selected by a mechatronic control module before they are immediately required. This provides a very smooth, almost unnoticeable, gear change that is extremely efficient. This system allows for faster acceleration and smoother shifting than either automatic or manual transmissions since it can essentially shift gears without any interruption in power. The TCU inside the mechatronic control module changes gears sequentially but can also carry out block changes between odd and even gear sets to provide even faster gear changes, and what’s even better is that this style of TCU will learn and adapt to the driver of the vehicle and their driving style.

The progression of modern transmissions and their ever more sophisticated control units have had the effect of simplifying driving for the motorist, while increasing the power output and shortening acceleration times, however the complexity of each system can be astounding. Each design and iteration that follows will comprise in a network of varying components for each, but will mostly be inclusive of sensor and switch inputs, electronic control units, motors and actuators.

The cause of transmission ECU/controller malfunction varies between design type and manufacturer. Circuit overload, component and manufacturing defects, fluid ingress, solenoid or internal sensor failure, the list is almost endless. But in either case, the symptoms that these failures cause are not too dissimilar from one another:

- ‘F’ or ‘N’ flashing in gear display

- ‘Transmission visit workshop’ warning message on dashboard

- PRNDS light flashing

- Banging into gear

- Harsh or jerky gear change

- Gears sticking

- Dropping out of gear

- No drive gear selection

- No reverse gear selection

- Limp home mode / safe mode

- Loss of power

- Failure of the vehicle to start

Videos:

Mercedes Transmission 7GTRONIC 722.9 Conductor Plate Problems:

Audi/Volkswagen DQ200 DSG 7 Speed Mechatronic Problems:

DSG7 DQ200 Gearbox Mechatronic - Unable to Select Gear - Fixed:

DSG 7 Speed Mechatronic Installation (DQ200):

Audi S Tronic Gearbox Problems:

Range Rover Sport and Evoque Gear Selector Problem - FIXED!!:

Test and rebuild:

Using our bespoke Hardware In-The-Loop rigs our technicians will test your transmission controller under real-world conditions before and after the rebuild to safeguard that no faults remain and ensure that each unit meets or exceeds original specifications. Applying innovative reverse engineering and remanufacture procedures, along with only using higher rated than standard components, you can be sure that once rebuilt, your transmission control unit will not fail again.

Programming:

Each transmission unit is exclusively programmed to the vehicle and can cost a pretty penny to have recoded. That’s why we retain all programming and coding information during test and rebuild, we don’t want you to have to spend out unnecessarily so we have perfected our testing to ensure that all you need to do is – refit and drive.

Quality:

The quality of our work speaks for itself. Our team is made up exclusively of professionals, who are dedicated to providing you with nothing but the best service possible. We have been the number one choice for franchise main dealerships and specialists around the globe for countless years due to our focus on quality assurance, efficiency, technical support and investment into future technology.

Warranty:

Lifetime unlimited mileage*

How do I get my unit rebuilt?

To pay for the rebuild click the Shop Now link above to view our product catalogue, select your vehicle and transmission control unit and then click: Get yours rebuilt.

Print the payment/booking confirmation email.

Package the control unit inside a sturdy box with plenty of packaging material (make sure you include your confirmation email in the box).

Send us your package by tracked courier (the shipping instructions are on the confirmation email).

Once received we will test, rebuild and return your unit with an unlimited mileage lifetime warranty. (if your unit turns out not to be faulty then we will refund your payment less a small testing fee and return shipping)

What if I don’t want to pay up front?

This is not a problem, if you prefer this option then follow the following steps:

Fill in and submit this test form.

Print the booking confirmation email.

Package the transmission ECU inside a sturdy box with plenty of packaging material (make sure you include your confirmation email in the box).

Send us your package by tracked courier (the shipping instructions are on the confirmation email).

Once received, we will test your transmission controller and call you to advise on the outcome of testing, if your TCM unit is faulty and you choose to go ahead with the rebuild then we will take payment over the phone using a debit/credit card.

We will then rebuild your unit and return it to you with an unlimited mileage warranty.

If you require further information regarding these transmission controllers then please contact us.